Flex Durability Tester factory commercial|flex resistance tester : broker The Flex Durability Tester simulates stress, which flexible packaging materials (such as coated or vapor-coated paper, plastic films and laminated material) may be subject during the automated packaging process. The KFT-C covers the determination of the flex resistance of flexible barrier

WEBSuzy Cortez: ex-Miss Bumbum é uma das musas do OnlyFans no Brasil. Ela tem um dos perfis mais acessados da plataforma de conteúdo adulto. Compartilha fotos e vídeos .

{plog:ftitle_list}

Resultado da 7 de dez. de 2022 · 46 curtidas,Vídeo do TikTok de °•Geo_chan•° ↞ (@geovana_chan): "q soft gnt kk".som original - °•Geo_chan•° ↞.

Overview. Standards. Applications. Features. Configurations. i-Flexdura 9100 Flex Durability Tester is used for simulating a creasing strain to which flexible packaging materials may be subject during machine processing or during the packaging process. It covers the determination of the flex resistance of flexible barrier materials.

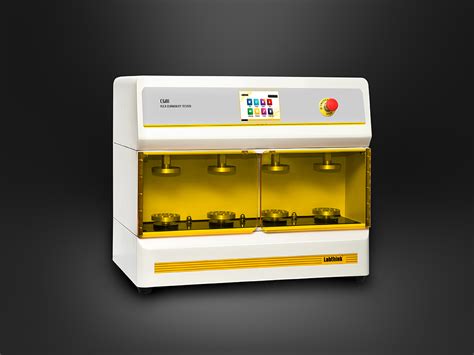

The Gelbo Flex Durability Tester GFT392 is designed for Flexible Barrier Materials and complies with ASTM test method F392. Available in 120 VAC or 220 VAC. Request a Quote Download Brochure.Flex durability tester for Flexible Barrier Materials Complies with ASTM test method F392 Introduction: This instrument has been designed to determine the flex resistance of the flexible barrier materials by applying repetitive strain. Pinhole formations are the criteria for measuring failure and are determined by use of coloredThe headquarters of Labthink is in Jinan, China; its international headquarters is in Boston, USA. Labthink has more than 50 international distributors and more than 30 international service providers.Q-Card’s bend and torsion card durability tester is designed to assess the resistance of plastic magnetic stripe and chip cards. Heavy duty construction and simultaneous A axis, B axis and torsion testing makes this equipment ideal .

The Flex Durability Tester simulates stress, which flexible packaging materials (such as coated or vapor-coated paper, plastic films and laminated material) may be subject during the automated packaging process. The KFT-C covers the determination of the flex resistance of flexible barrier We do the flex durability test with Labthink’s C681M Flex Durability Tester. The test standard is ASTM F392. The flexible specimens are flexed at standard atmospheric conditions (23℃ and 50% relative humidity) unless otherwise specified. Flexing conditions and number and severity of flexing strokes vary with the type of structure being tested.

flex resistance tester

At Cell Instruments, we take pride in offering state-of-the-art testing instruments, and our Flex Durability Tester stands as a testament to our commitment to quality. Whether you are in the packaging, food, medicine, beverage, or academic industries, our Flex Durability Tester ensures that your materials meet the highest standards.Test Results best in class ~40% worse ~25% worse ~20% worse UV Resistant Plastic uknown uknown uknown Superior hardware design with high margin components for ultimate durability Full Line-Voltage Disconnect Capability for Better Compressor Protection Open Compressor Overload Detection Stall Detection (compressor rotational speed) Scope1.1 This test method covers the determination of the flex resistance of flexible barrier materials. Pinhole formation is the criterion presented for measuring failure, but other tests such as gas-transmission rates can be used in place of the pinhole

The flex durability is the ability of a material to resist flexing or kneading during production and transportation. Permeability test often comes after the flex process to ensure the overall performance of packaging materials. ASTM F392 - Standard Test Method for Flex Durability of Flexible Barrier MaterialsGelbo Flex Tester designed to measure flexible barrier materials for flex durability to ASTM F392. The GF-392 Gelbo Flex Tester is a microprocessor controlled system, with a user controllable pre-set method programmed for ASTM F392. This makes the GF-392 both versatile and very easy to use, with only minimal user training needing.There are 5 pre-programed test conditions to choose from: Mode A– Full flex for 1 hour (2,700 cycles), Mode B– Full flex for 20 minutes (900 cycles), Mode C– Full flex for 6 minutes (270 cycles), Mode D– Full flex for 20 cycles, Mode E– Partial flex for 20 cycles. Technical Features. PLC control and HMI touch screen operationThe GFT-01 flex durability tester is used to measure the resis-tance against repetitive strain for films, composites and coating films, etc. Flex failure is determined by measuring the pinholes formed in the sample structure. It is also called Gelboflex. Principle The sample size (200 by 280 mm) is attached to the flex tester mandrels.

The Gelbo Flex Durability Tester GFT392 is designed for Flexible Barrier Materials and complies with ASTM test method F392. Available in 120 VAC or 220 VAC.h.

Buyer Feedback and Testing: Suppliers steadily share customer testimonials and case studies to highlight the durability of their products in real-world applications. Feedback from users who’ve put in LED Neon Flex in varied settings can provide valuable insights into the performance and longevity of the product.o Condition C – full flex for 6 minutes (270 cycles) o Condition D – full flex for 20 cycles o Condition E – partial flex only for 20 cycles • For more details about ASTM F392, please see . Standard Practice for Conditioning Flexible Barrier Materials for Flex Durability. on the ASTM website. Instrument Utilized: Gelbo Flex Tester . NotesFlex durability testing of materials is a new test item emerged with the increasing demand for package testing. 1.Measuring Demand for Flex Durability 1.1 What is Flex Durability? Flex Durability refers to the capacity of deformed materials under pressure to maintain its stable property after the external forces is removed.6. Test Specimens—All Conditions 6.1 Cut the samples into 200 by 280-mm (8 by 11-in.) flat sheets with the 200-mm dimension in the direction to be tested. This will also be in the direction of the flex-tester axis. 6.2 Flex test four specimens in their machine direction and four in their transverse direction. In addition, test a control set

flex durability would be obtained by measuring the changes in number of pinholes or barrier properties after test, which could provide quantitative basis for package design and practical usage. Functionality 5 standard test modes and 4 specimen stations support various combinations of non-standard test conditions FDT-02 Flex Durability Tester (ASTM F392) is professionally applicable to the determination of flex durability of flexible films, composite films, and coatin.

Paper Materials Test the flex durability of paper materials Technical Specifications Specification C681M Flex Frequency 45 cpm Test Mode Condition A (2700 cycles), Condition B (900 cycles), Condition C (270 cycles), Condition D (20 cycles), Condition E (20 cycles partial flex), Condition F (0~20000 cycles) Tensile & Pressing Force 300 NThe flex durability would be obtained by measuring the changes in number of pinholes or barrier properties after test, which could provide quantitative basis for package design and practical usage. Professional Technology 5 standard test modes and 4 specimen stations support various combinations of non-standard test conditions is factory tested and certified to the specified card deflection dimensions for each standard. Each set of jaws holds . cards. Torsion capacity is ten cards. B axis capacity is ten cards. ISO/CQM Version (110V) Dynamic Bend and Torsion Card Durability Tester ISO/CQM Version (220V) Dynamic Bend and Torsion Card Durability Tester ANSI Version .2. The testing range is different: the Martindale abrasion tester is mainly used to test the pilling ability of textiles to judge the durability of fabrics, while Scott Type crease-flex abrasion tester not only can test the durability of textiles but also can test the rubbed strength of the plastic film, artificial leather, rubber cloth and .

Download figure: Standard image High-resolution image Sufficient reliability and durability are essential for the popularization of FCEVs as competitive commercial products. 14,15 Many reports in the literature have focused on durability issues such as gas crossover through the electrolyte membrane; gas leakage from fuel cell stacks; and general deterioration .

RTT-01 Flex Durability Tester is professionally applicable to the determination of flex durability of flexible films, composite films and coating films. The instrument can simulate the kneading and creasing behaviors of films happened during production, processing and transportation. The flex durability can be obtained by measuring the changes in number of pinholes or barrier .The Gelbo Flex Durability Tester GFT392 is designed for Flexible Barrier Materials and complies with ASTM test method F392. Available in 120 VAC or 220 VAC. Request a Quote Download Brochure. Description. This instrument has been designed to determine the flex resistance of flexible barrier materials by applying repetitive strain. Pinholes .

flex durability tester

Ericeira | Praia do Sul. Nublado.A temperatura registada é de 11º.; O Índice UV é de 3.O vento sopra de N, com 26.3km/h.; A temperatura da água é de 14.5º.A ondulação entra .

Flex Durability Tester factory commercial|flex resistance tester